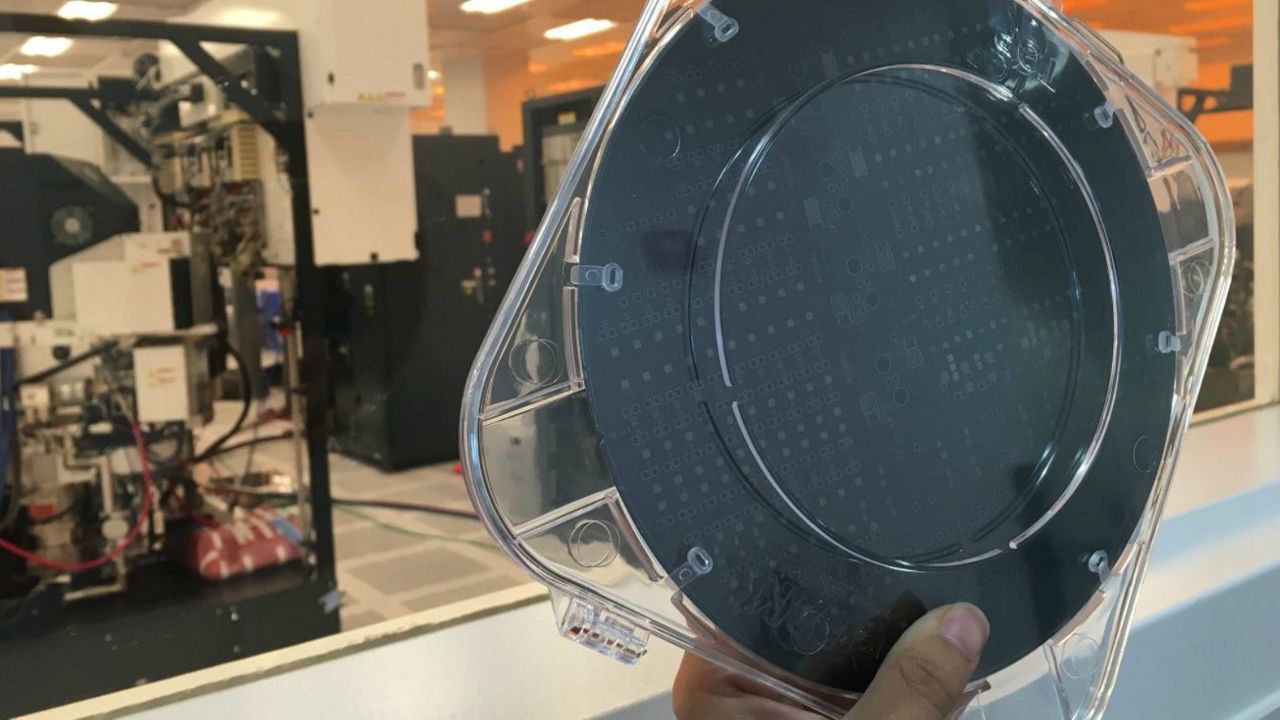

KISSIMMEE, Fla. -- A high-tech, advanced manufacturing facility poised to change perceptions about Osceola County just achieved a huge milestone -- processing their first silicon wafer.

Those get broken down into tiny sensors, the foundation for microelectronic devices.

- Manufacturing facility in Kissimmee processes first silicon wafer

- NeoCity in Osceola is tech district poised to transform economy

- STEM high school to eventually make it to district

“It is a very big deal," said engineer Ankineedu Velaga. “Engineers live for this."

Velaga runs the fabrication lab at BRIDG, a nanotechnology manufacturing facility in Kissimmee, located off U.S. 192 by the Turnpike.

About a year ago, BRIDG -- then called ICAMR -- was just dirt. Now, it’s the first part of an advanced manufacturing park called NeoCity: 500 acres owned by Osceola County, designed to be the next high-tech corridor, transforming their economy.

“For Osceola County to be bold enough to say we want to create a new pillar in our economy," said Chester Kennedy, the CEO of BRIDG. “It’s been an amazing transformation over the last year and a half.”

Kennedy said at his company, everyone celebrated their successful wafer testing, as the 8-inch silicon wafer made its way through a stepper.

But, BRIDG is already looking to the future: more processes will follow -- equipment readied after being in storage for months. In a few weeks, they'll be able to build a functional device.

“These sensors are going to impact every area of our lives, from the way that we manage our own health to the way that we drive or are driven around," said Kennedy. “We’re bridging that innovation to development gap to let people who have those bold ideas have a pathway to get them into a commercialized product.”

It's a capability, Kennedy explained, largely in privately-held companies, like Intel or IBM, and simply not addressable by individuals or smaller businesses.

On the second floor of BRIDG, engineers suit up, flapping on latex gloves, masks and white "bunny suits" to enter the sterile, clean space of the fab lab.

Adjacent to the BRIDG facility, dirt continues to move, crews today pouring concrete for a 100,000 sq. ft. office building set to open within the next year.

More customers are waiting to use the lab space, according to Kennedy, and his not-for-profit entity can easily transition some operations to the new space.

One of BRIDG's early partners, a global leader in nanotechnology from Belgium, is still on site. Design service IMEC works on LiDAR technology with autonomous vehicles, as well as security tech -- like that which is found in airport metal detectors -- shrinking it down.

They, too, will move some operations as the new office space is completed.

And eventually, a STEM high school, called NeoCity Academy, will open its doors, with BRIDG engineers serving as faculty members.